Customized Aerospace & Defense Interconnect Solutions

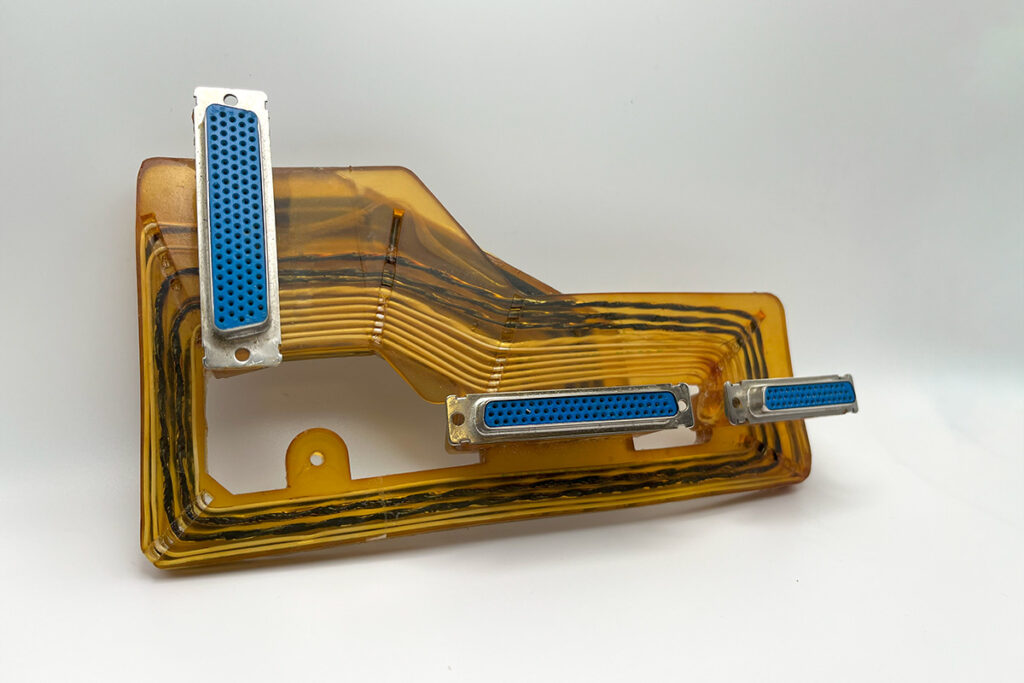

Flat Molded Cable Assemblies

Experience high flex life and supreme adaptability with flat molded cables. Customized design allows them to transform into 3D flexible cables, perfect for tight spaces and transitioning from flat to round. Thin molding walls minimize thickness and width. Benefit from ruggedness, environmental sealing, and EMI shielding for individual wires or overall. Ideal alternative to rigid flex PCBs for interconnection.

Engineered to offer unparalleled flexibility within a single plane, these custom-designed cables revolutionize your ability to navigate confined spaces and effortlessly transition between flat and 3D flex. Imagine the possibilities when you break free from the limitations of traditional cabling.

With slender molding walls, these cables maintain a sleek profile without compromising durability. They provide essential environmental sealing and optional EMI shielding, both at the wire level and for the entire assembly. These features not only ensure secure connections in harsh environments but also make them the superior choice for EMI-sensitive applications.

Beyond their physical design, these innovative cables offer the freedom to utilize any type of wire and cable, transcending material barriers. From FEP-insulated wires to polyurethane and silicone moldings, our product provides a spectrum of customization options that empower you to build a system that perfectly aligns with your requirements.

Advantages of Flat Molded Cable Assemblies

Flat molded cables provide high flex life with flexibility typically in one plane. Nortech can design flat cables to change planes to become three dimensional flexible cables. They can be configured to fit into tight spaces and transition from flat to round and back. Very thin molding walls can be provided to minimize thickness and width. The molding over the conductors provides ruggedness and environmental sealing. Flat molded cables can be used in place of rigid flex PCB’s for interconnection. EMI shielding can be provided as overall shielding or individual wire/cable shielding.

Materials

Wire and Cable

Any type of wire and cable can be used in a flat molded cable. Wire can be insulated or uninsulated. Wire size can be very large or 32 AWG or smaller.

Ultra Flexible

For ultra flexible use, Nortech recommends wire in accordance with MIS-35755. This specification is for FEP insulated wires with multiple or single conductors, with or without shielding, with high strand count for flexibility. This wire should not be used in open wire harnesses.

Molding Material

Typical molding materials are polyurethane or silicone.

- Polyurethane per MIS-35759 (Henkel US4028NM) provides an amber colored polyurethane with low hardness.

- Polurethane per MIL-M-24041 Category B Type 1 is used where a higher hardness is desired.

- Silicone per Dow Corning Sylgard® 186 is a good choice for flexibility, tear resistance, and optical clarity.

EMI Shielding

Individual EMI shielding can be provided through individual or twisted wire braids. Overall shielding can be provided through silver filled conductive coatings applied over the molded flat cable. The coating is applied after connector termination and molding to provide low resistance coverage from connector shell to connector shell.

A final non-conductive coating is available over the conductive coating to provide abrasion protection and electrical insulation.

Spacing and Wall Thickness

Mold material thickness over the wires and spacing between the wires can be as small as .016 inch to minimize flat cable dimensions.