In a world where data speed, power delivery, and reliability are paramount, Nortech is pushing the boundaries of...

Read More »We understand that integration is a significant challenge for interconnect solutions used in industrial applications, as these connections need to combine seamlessly with other components and systems, requiring a deep understanding of the entire system to ensure compatibility and reliable operation. We leverage our experience and expertise to ensure uninterrupted operation with other components and systems, resulting in optimized system performance, reduced costs, and increased customer satisfaction.

Expertise

Manufacturing

Customization is essential to designing and manufacturing interconnect solutions for industrial applications, which often necessitate bespoke solutions to meet specific requirements. Partnering with an interconnect innovator and world-class global electronics manufacturing services provider is crucial to addressing those customization challenges.

At Nortech, we provide experienced engineering support to optimize designs, select materials, and identify cost-saving opportunities. Our groundbreaking technology, expertise, experience, and capabilities enable us to optimize your designs, reduce costs, and let you stay ahead of the competition.

Achieving a balance between material and labor costs while ensuring high performance and reliability presents a significant challenge for industrial applications. Nortech provides the necessary expertise to optimize designs, select cost-effective materials and components, and identify opportunities for cost savings. We possess extensive in-house manufacturing capabilities, including wire preparation, component manufacturing, shielding, encapsulation, molding, termination connectors, complex assemblies, and tuning.

Moreover, we have experience in Designing for Manufacturability and Designing for Supply Chains, which enables us to proactively manage material availability and costs and ensure our clients receive the best value for their investment. We deliver optimized products that meet or exceed your expectations by identifying opportunities for streamlining production, reducing costs, and enhancing overall quality and performance.

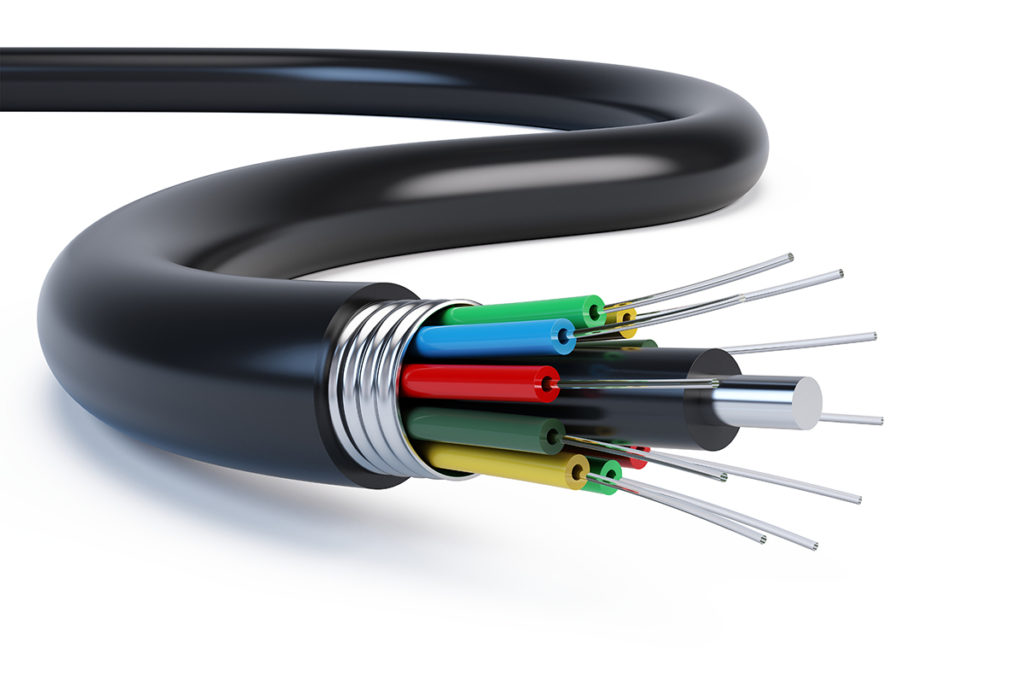

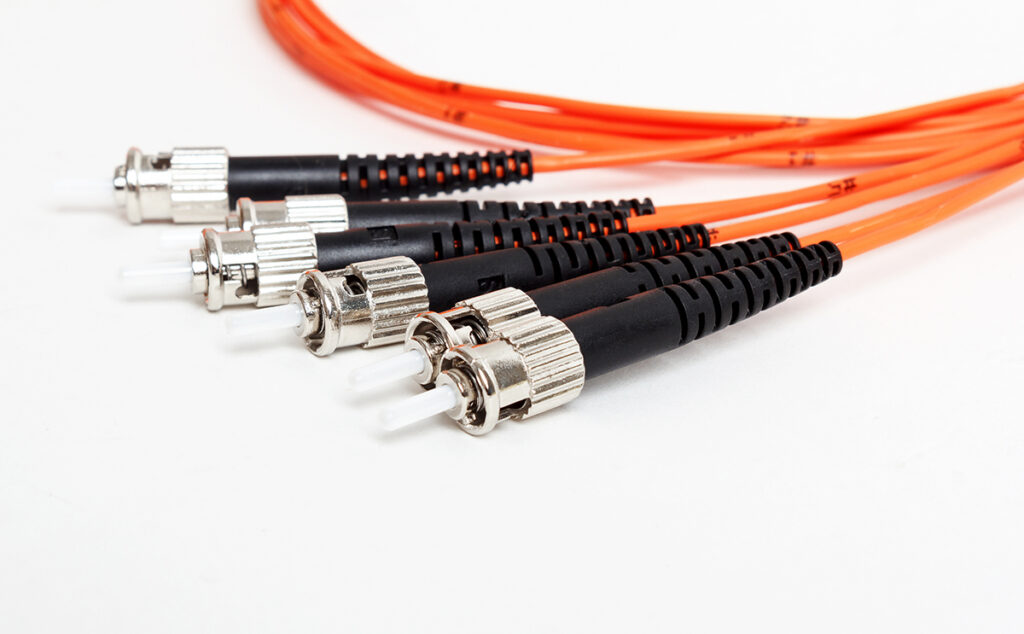

Partnering with an interconnect innovator ensures your wire and cable assemblies meet rigorous performance specifications and can operate reliably in industrial applications. We have the necessary equipment, facilities, and expertise to conduct testing and validation that meets the highest standards of quality and accuracy. This includes testing for environmental factors such as temperature, abrasion, water and chemical immersion, and EMI. Furthermore, Nortech can also conduct electrical testing and simulate wear and tear or extensive use, ensuring that the wire and cable assemblies will withstand the intended operating conditions.

By partnering with Nortech, you can be confident that you will have access to the best testing environments available, ensuring continued quality and reliability with maximum yields.

Our client faced challenges with inaccurate demand forecasts and inefficient component build schedules due to constantly shifting production schedules. By partnering with Nortech’s account team, the root cause of the issue was traced back to outdated MRP software and established a process to safeguard against fluctuations, including a stocking program for inventory on-hand.

Our team provided the solution to our client’s problem with managing multiple suppliers and design iterations. Nortech’s disciplined approach and flexible quality system created a clear and consistent path for device approval, eliminating unforeseen setbacks and minimizing gaps.

Through early engagement and leveraging our expertise, technology, and resources, we helped our client develop a detachable MRI table docking system. With our integrated team of engineers, daily progress updates, and data to streamline FDA approval, the technology designed and developed has been successfully implemented into healthcare facilities.

Are your projects being delayed because your engineering resources are over-allocated? Are inefficient design and testing leading to R&D cost overruns? Bring together your team with our in-house specialized resources to get everyone the answers they need on time and within budget.

In a world where data speed, power delivery, and reliability are paramount, Nortech is pushing the boundaries of...

Read More »Global manufacturing is entering a new era, shaped by shifting trade policies, technological advancements, and the urgent need...

Read More »The Role of AS9100 Certification in Quality-Driven Approach When reliability and safety are non-negotiable, quality management must take...

Read More »Cable assemblies are key components across industries, from medical, aerospace to military applications. Their reliability and protection from...

Read More »

Nortech Systems is a leading provider of design and manufacturing solutions for complex electromedical devices, electromechanical systems, assemblies, and components. Its manufacturing and supply chain capabilities are vertically integrated around wire, cable, and interconnect assemblies, printed circuit board assemblies, as well as system-level assembly, integration, and final test. Headquartered in Maple Grove, Minn., Nortech currently has six manufacturing locations and design centers across the U.S., Latin America, and Asia. Nortech Systems is traded on the NASDAQ Stock Market under the symbol NSYS.