Wearable medical devices have evolved from simple fitness trackers to sophisticated diagnostic tools that monitor everything from blood...

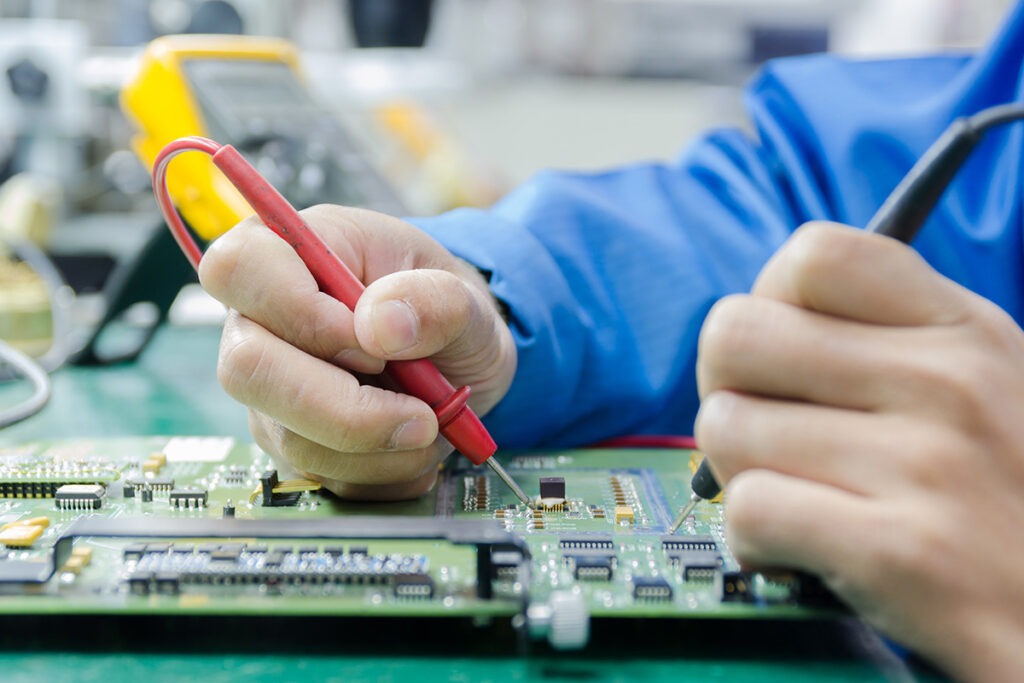

Read More »With over thirty years of experience in industrial PCBAs, Nortech is committed to delivering high-quality products that prioritize timely delivery and cost-effective solutions. Critical processes such as PCB layout, Design for Manufacturing analysis (DFM), and Design for Test analysis (DFT) are essential for the functionality and reliability of these industrial assemblies. Additionally, our solutions are tailored for low to medium volume, high-mix production environments, requiring flexibility and scalability.

With over thirty years of experience in industrial PCBAs, Nortech is committed to delivering high-quality products that prioritize timely delivery and cost-effective solutions. Critical processes such as PCB layout, Design for Manufacturing analysis (DFM), and Design for Test analysis (DFT) are essential for the functionality and reliability of these industrial assemblies. Additionally, our solutions are tailored for low to medium volume, high-mix production environments, requiring flexibility and scalability.

Nortech is your partner for industrial PCB assembly. We specialize in low to medium volume, high-mix production, allowing us to quickly adapt to your evolving needs. We provide customized solutions for your industrial PCB assemblies.

Leveraging our extensive global network, we deliver critical components quickly and reliably. Combined with our customized inventory solutions, we streamline your supply chain for uninterrupted production. Our strategic sourcing and inventory management strategies reduce costs without compromising quality or delivery. Benefit from our global reach and supply chain expertise.

Design for Manufacturing (DFM) issues can significantly impact the efficiency and quality of printed circuit board assembly (PCBA). Common challenges arise when there is a lack of communication between designers and manufacturers, leading to mismatches in component layouts, potential supply chain issues, and configuration incompatibilities. These misalignments can ultimately result in project delays, increased costs, and compromised product functionality. Notably, design flaws like component misplacement and inadequate spacing can complicate assembly processes and raise concerns about the overall performance of the end product.

To mitigate these issues, it is imperative to establish well-defined functional and physical requirements during the PCBA design phase, ensuring considerations around form factor, layer count, and cost-performance trade-offs are addressed. Moreover, developing comprehensive test requirements and maintaining an issues log can promote a synergy between design and manufacturing, facilitating proactive problem-solving. Flexibility in supplier selection, along with a commitment to DFM principles, is key to achieving high-quality PCBA outcomes, ultimately enhancing the reliability and effectiveness of critical systems across various industries.

Nortech offers a diverse range of PCBA design and manufacturing technologies, enabling us to help transform your ideal prototype into a fully functional, aesthetically pleasing, and refined product ready for implementation.

Printed Circuit Board Assembly (PCBA) Capabilities for the Industrial Market:

Wearable medical devices have evolved from simple fitness trackers to sophisticated diagnostic tools that monitor everything from blood...

Read More »High-Performance Flexible Circuit Flex Faraday Xtreme™ Military personnel operate in environments where equipment failure isn’t just inconvenient, it’s...

Read More »https://youtu.be/Fxshro3Ns5A?si=vQr9k6JC3Am4WRqc In a world where data speed, power delivery, and reliability are paramount, Nortech is pushing the boundaries...

Read More »Global manufacturing is entering a new era, shaped by shifting trade policies, technological advancements, and the urgent need...

Read More »