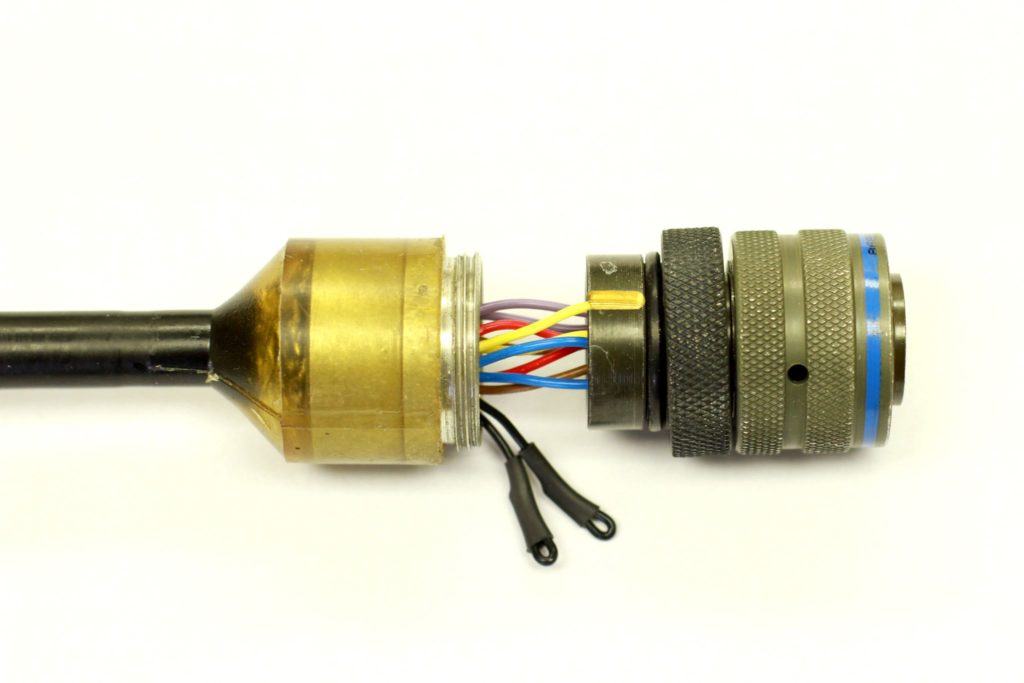

A cable harness assembly is typically a configuration of electrical cables or wires protected by a molding or environmental-proof backshell. Used to transmit power and signals, these harnesses can range from simple commercial applications to multi-legged assemblies with complex breakouts and junctions like those used more often for defense, medical, or industrial applications.

Some assemblies may have designed enclosures and connections within the enclosure. Other assemblies may have more robust features designed to withstand rugged environments, weather events, or even hold up to pedestrian or vehicular traffic.

Whether your design is frozen and you are just looking to transfer it to a production facility, or you are still in the concept phase and would like assistance finalizing a design, there are several factors to consider before releasing your project to the production floor.

One of those factors is ensuring you are working with a capable, experienced manufacturer like Nortech Systems. Read on for additional cable harness assembly design considerations, then contact us to help you achieve your goals regardless of where you are in the design process.

Purpose and Environment

The first step to creating a cable harness assembly design is to define its purpose and functionality. You will need to provide minimum necessary information for a standard design transfer to meet those goals. That information includes:

- Desired connectors or mating interface specifications

- Wiring diagrams, including core material specifications and gauge

- Internal and external shielding requirements

The above information is often prescribed based on the environmental conditions the assembly must withstand. Design specifications require knowing whether the assembly needs to be immersion-proof in general or if it is subject to specific IP Ratings for protection against solids and liquids.

These IP Ratings define the size of solid particulate allowed to penetrate the assembly from greater than 50mm to no dust ingress. These ratings also define the amount of liquid allowed to infiltrate an assembly from falling drops of water at prescribed angles to protection against long periods in water under pressure.

Additional environmental condition requirements that you should identify and provide specifications for during the design phase may include, but are certainly not limited to:

- Utilizing specific materials in the assembly

- Recognizing specific temperature ratings

- Adhering to EMI/RFI interference or emission standards

- Accounting for vibration, erosion, or high flexure exposure

- Allowing for various installation scenarios

- Accommodating field maintenance access

- Planning for service life expectations

Component Definition and Layout

Once you have established the general configuration requirements of the cable harness assembly, the next step is to begin specifying the individual components. Typical design decisions required by component include:

- Conducting material, typically copper wire, and the desired gauges and length

- Insulation material with standard options being Teflon or PVC

- Thermoplastic or thermoset jackets

- Connector and/or interface types

- Overmolding

- Heat shrink or direct print labels

- Backshells with or without cable clamps

- Taping and straps

Specifying components will also need to be done in conjunction with the physical layout considerations, such as:

- Clocking and determining the location of the main keyway

- Branching into Y- or T-branch configurations

- Spacing allowances for desired rigidity, flexibility, and access

Design for Manufacturability (DFM)

One last design consideration when creating cable harness assemblies is Designing for Manufacturability. For a successful production run from the start, the component definitions and layouts should also guarantee a smooth transition to production.

You can avoid typical manufacturing problems by completing the following during the design phase:

- Verifying that the BOM is complete and accurate in comparison to the design

- Checking on component availability, keeping Supply Chain constraints in mind

- Confirming that individual components fit into the final layout accurately

- Ensuring that specified components will take solder appropriately

- Checking that the outlined assembly process is within the range of available production equipment or working with the manufacturing team to make modifications

- Laying out branching schematics ahead of time to avoid changing assembly operations

Again, this list is not exhaustive but covers some common DFM issues encountered during cable harness assembly production.

Nortech Systems for Cable Harness Assembly

The environmental considerations, component definitions, and DFM issues to avoid listed in this article are just the tip of the iceberg when it comes to creating the complexities of a cable harness assembly. At Nortech Systems, handling highly complex designs and assemblies is our specialty. Give us a mold envelope, and we will exceed your expectations for designing or refining a high-quality, cost-effective assembly, whether you are just starting your design process or have some of the basic components already laid out.

If you have a design ready to hand off to production, make sure you are working with Nortech Systems, a manufacturer with a wide range of technology and tooling options already available. We also specialize in low volume/high mix production, a highly desired option in the electronics manufacturing industry.

Source inspections, government inspections, or qualification documentation can also be a stumbling block for some manufacturers. With our vast experience handling aerospace and defense contracts and providing components for medical equipment, verifying and documenting data is another project aspect in which we excel.

Pull together your back-of-the-envelope notes or gather your completed specifications to the cloud. Then, contact us to get started.