Flat Cable Solutions: Integrating Shielding & Reliability

Our world is demanding smaller, faster, and more powerful electronic systems every day. Within these systems, the innovative anchoring components also need to evolve. For electronics engineers, the integration of EMI shielded flat cables for aerospace defense is an significant component of the overall design.

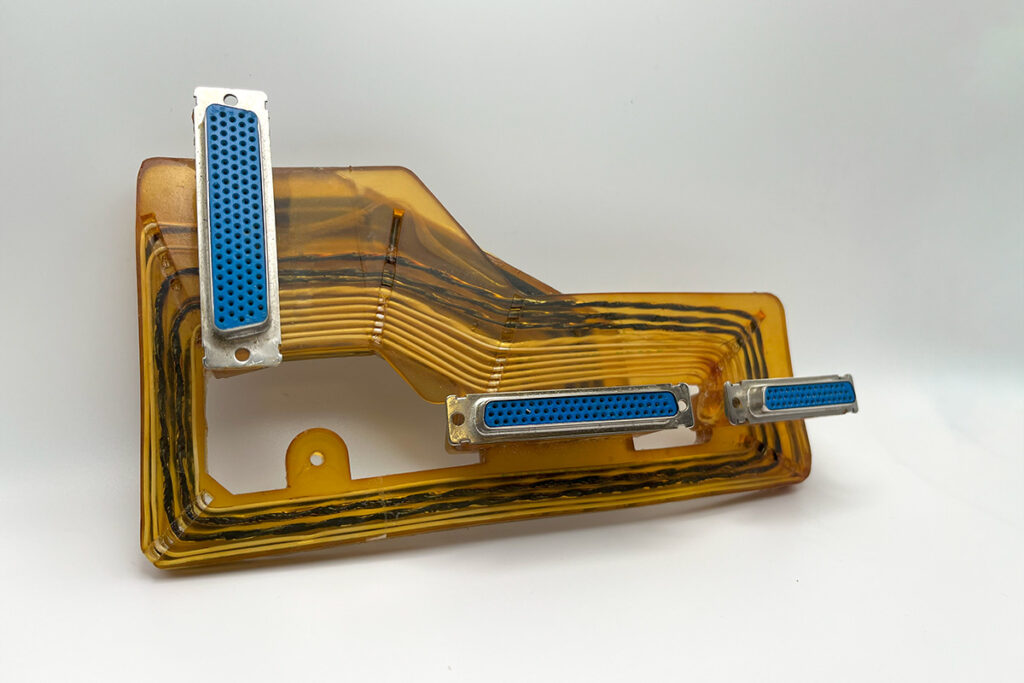

These flat, molded cable assemblies are redefining what’s possible in terms of design flexibility. Ironically, what’s often overlooked is how shielding and reliability are seamlessly woven into these solutions. Flat molded cable assemblies are composed of conductors enclosed within a flexible thermoplastic polyurethane material in a flat shape. Usually, one or two layers are arranged parallel in a thin and wide layout.

Unseen Heroes of Modern Engineering

Underneath the sleek exteriors of our high-tech gadgets and aerospace devices is a labyrinth of cables. Each cable serves as a vital artery within the body of the system. The unsung heroes of these systems are often flat cables. This thin, wide, and flexible technology allows for innovative design and packaging within a confined space. However, their significance in the grand scheme of electronic design far exceeds their slender profile.

Benefits of EMI Shielded Flat Cables for Aerospace Defense

Designed with a parallel arrangement of conductors enclosed in flexible materials, flat cables provide more than just a connection; they offer a solution that adapts to the rigors of modern electronics. Explore the many benefits of EMI shielded flat cables for aerospace defense below.

1. Unmatched Flexibility

Unlike traditional round cables, flat cables offer bending flexibility in a single plane. This is essential for designs that require high movement or tight spaces. Having adaptability allows for creative routing and the ability to conserve space within the system. This is a highly prized feature in industries marked by ever-shrinking technological boundaries.

Nortech can design flat cables that change planes to become 3-dimensional flexible cables. EMI shielded flat cables for aerospace defense can be configured to fit into tight spaces and transition from flat to round and back. Very thin molding walls made from thermoplastic polyurethane can be provided to minimize thickness and width. The flexible polyurethane or silicone molding over the conductors provides ruggedness and environmental sealing. Flat molded cables can be used in place of rigid-flex PCB’s for interconnection.

2. Sleek Durability

EMI shielded flat cables for aerospace defense are resilient. The molding over the conductors isn’t just for aesthetics. It ensures the ruggedness required to withstand the challenges of daily use, especially in mission-critical applications where system failures could have catastrophic implications.

3. Shielding: The Silent Guardian

Electronic components have a shielding that plays the role of the silent protector. It defends against an invisible enemy: Electromagnetic Interference (EMI). Shielding is particularly critical in current applications where devices are densely packed and the risk of cross-talk and signal degradation is high. EMI shielding can be provided as overall shielding or individual wire/cable shielding.

4. Dynamic Strength & Size

As we’ve established, flat cables have a natural inclination towards a slim and trim profile, ideal for compact systems. However, incorporating effective shielding into this geometry presents a unique set of challenges. Engineers must navigate the delicate balance between providing robust protection and maintaining the necessary form factor.

5. Shrouding the Signal

Several innovative techniques and materials offer viable solutions for the shielding of flat cables. From silver-filled conductive coatings for overall EMI shielding to individual wire/cable shielding setups, the array of options is as diverse as the applications that need them.

6. Solid Base of Reliability

In the constrained spaces of modern electronics, reliability is non-negotiable. A system is only as strong as its weakest link, and flat cable solutions with integrated durability set an uncompromising standard for dependability.

Factors That Test Fortitude

The road to reliability is paved with many twists and turns that could affect performance of flat cable solutions. Stress on joints from excessive bending, vibration in aerospace applications, and even something as small as dust can lead to wear and tear. Although minimal, these things can ultimately reduce the lifespan of the system.

There are many promising strategies to prevent these downfalls. Careful selection of materials, like ultra-flexible wires, and incorporating protective sheaths are just the beginning. The real testament to reliability lies in the meticulous testing and quality control processes by manufacturers. These processes are used to ensure their flat cable solutions can weather any storm.

The New Standard in Electronic Design

Winding down our look into EMI shielded flat cables for aerospace defense, it’s clear that shielding integration and enhanced reliability is no longer a luxury, but a necessity. By embracing these advancements in electronic design, industries can solve current challenges and also proactively meet the demands of future technologies.

As connectors of the future take shape in our imaginations, integration of these auxiliary features will set the standard in electronic design. The shielded and reliable flat cable promises a more connected, safer and efficient world.

Contact Nortech to learn how we can help you with EMI shielded flat cables for aerospace defense now!