In the heart of southern Minnesota, our Mankato facility serves as a global Center of Excellence for PCB assembly manufacturing. It’s more than just a manufacturing site. This special location embodies Nortech’s commitment to solving complex engineering challenges and delivering mission-critical reliability. Mankato is yet another location serving as a true partner to our customers across defense, medical, and industrial markets.

Innovation & Complex Problem Solving

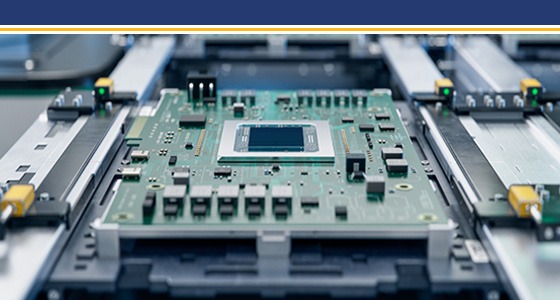

At Nortech Mankato, innovation begins with a focus on low-volume, high-mix production. This is a space where flexibility, precision, and experience make all the difference. Our team specializes in tackling the kinds of challenges that other manufacturers shy away from: complex assemblies, evolving requirements, and demanding applications where performance is non-negotiable.

Sr. VP of Global Operations, John Lindeen says, “We really emphasize on solving hard, complex problems related to low-volume/ high-mix, and the PCBAs. Our customers are usually in the defense and medical industry with a little bit of industrial applications spread through it.”

Design Through Production Under One Roof

One defining strength of the Mankato facility is its end-to-end capability. From initial concept and design to prototyping, testing, and full-scale production, everything happens within one integrated system.

“We not only have design capabilities, but we also have manufacturing capabilities all within one umbrella. And our customers find that useful because they basically have a one-stop-shop to get everything from a napkin sketch to product realization,” explains Brad Reiman, Engineering Manager.

“For instance, we have auto-insert, which a lot of companies don’t currently do that because it’s kind of an older technology. But we have automated equipment to be able to do that,” says Reiman.

That comprehensive approach includes both modern and legacy capabilities. While the facility is equipped with advanced surface mount and through-hole technologies, it also maintains specialized processes like auto insertion. Such technology is a capability few manufacturers retain today.

Mankato also excels at ruggedization through potting, conformal coating, and hand assembly. These methods ensure durability in extreme conditions. In addition, Mankato’s engineers can integrate multiple component types, such as cable assemblies and PCBAs, into a complete box-build solution.

Mission-Critical Quality and Precision

Every product that passes through Nortech Mankato plays a role in something bigger. Whether it’s supporting soldiers in the field or doctors in operating rooms, Nortech is ready to help.

“What we do and what our customers expect is that we have zero defects at all times,” says Brooke Prestegard, Director of Operations. “Nortech Systems provides mission critical, life-saving components for all our segments. For defense and aerospace, for the soldiers that are on the ground to anyone that’s in care of our medical hospitals and such for patients.”

To maintain these high standards, the facility operates under ISO 13485 and AS9100 certifications, ensuring adherence to rigorous quality and regulatory requirements.

Advanced Testing for Every Application

Testing is another area where Mankato sets itself apart. The facility offers a variety of advanced testing capabilities, including flying probe, hybrid functional and in-circuit testing (ICT), and full ICT platforms. These flexible testing options allow Nortech to create cost-effective, customized solutions tailored to each customer’s needs. It also guarantees better performance and reliability before your products ever reach the field.

Powered by People, Process, and Partnership

Behind every successful build is a team of dedicated professionals. Many of Mankato’s employees have been with Nortech for years. Our PCB assembly manufacturing team brings deep expertise and consistency to every project. That experience is supported by well-defined, proven processes that have been developed over time. It’s details like this that contribute to higher product quality and smooth new product introduction.

“There’s three things that separate Nortech’s Mankato from other competitors: it’s our people and how we train them, the processes that we’ve identified that are very tried and true for implementation of new product, as well as quality delivery. And the last thing is our capabilities.

That sense of partnership is central to the Mankato culture. “One customer said it best to me that Nortech is really viewed as a trusted partner,” Lindeen recalls. “We really see ourselves as an extension of our customer that we’re working with and have good, hard, collaborative discussions.”

A Trusted Partner in PCB Assembly Manufacturing

From design to delivery, our Mankato location exemplifies what it means to be a Center of Excellence. Nortech is a place where experience, technology, and teamwork come together to produce exceptional results. Whether developing ruggedized defense electronics or precision medical components, our team’s dedication to quality, collaboration, and innovation shines through in every product.

Get started on your next project with us today! Contact a Nortech representative now.