In the ever-evolving world of technology, the demand for reliable, high-speed data transmission is paramount. Nortech’s latest innovation, the non-magnetic expanded beam fiber optic patent, introduces a groundbreaking solution that integrates both optical and electrical elements using expanded beam technology. This patent reimagines the way we think about connectivity, especially in environments where reliability and performance are critical. In this blog post, we’ll delve into the intricacies of this patent, exploring its key technical features, applications, and the technology that makes it a game-changer.

At the heart of the non-magnetic expanded beam fiber optic patent is expanded beam technology. Unlike traditional physical contact (PC) connectors, which rely on direct contact between fiber ends, expanded beam connectors use lenses to expand the diameter of the light beam as it exits the fiber optic cable. This expanded beam is then collimated (made parallel) and refocused into the receiving fiber. This method offers several advantages:

- Reduced Contamination Impact: By expanding the beam, any contamination (dust, particles, etc.) is distributed over a larger area, significantly reducing its impact on signal quality.

- Enhanced Reliability: The non-contact nature of expanded beam connectors means there is no physical wear and tear on the fiber end faces, leading to longer-lasting connections.

- Improved Performance: Expanded beam connectors offer better insertion loss performance (less signal power loss) and reduced back reflection (less signal bouncing back to the source).

- Ruggedized Applications: These connectors are highly resilient to vibrations and harsh environmental conditions, making them ideal for applications in challenging environments like medical imaging (MRI machines) and industrial settings.

Key Features of the Non-Magnetic Expanded Beam Fiber Optic Cable Patent

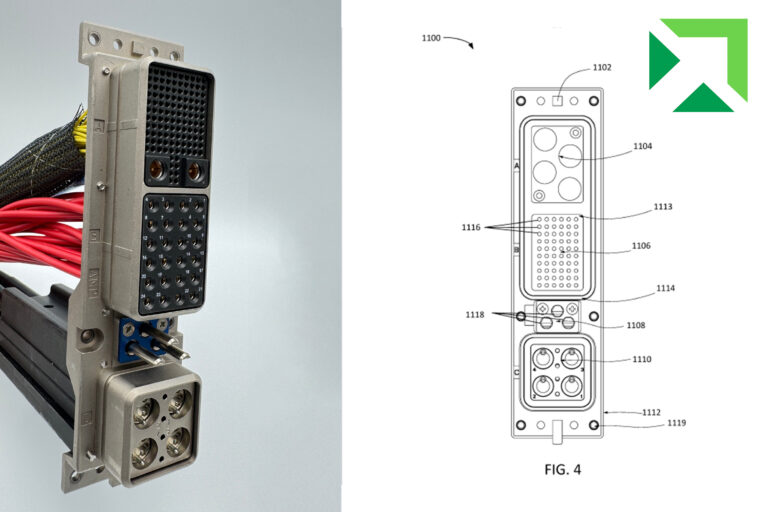

Hybrid Cabling Solution

The non-magnetic expanded beam fiber optic patent describes a non-magnetic hybrid cabling solution that integrates both optical and electrical elements. This hybrid approach enables the mixed-mode delivery of electro-optical signals, control, timing, and data. The system’s hybrid capabilities make it suitable for applications requiring high mating cycles and ruggedized characteristics.The non-magnetic expanded beam fiber optic patent describes a non-magnetic hybrid cabling solution that integrates both optical and electrical elements. This hybrid approach enables the mixed-mode delivery of electro-optical signals, control, timing, and data. The system’s hybrid capabilities make it suitable for applications requiring high mating cycles and ruggedized characteristics.

Precision Lens Technology

The patent leverages precision lens technology to expand the diameter of light beams. This minimizes the negative impacts of contamination and enhances insertion loss performance. The use of Gradient-Index (GRIN) lenses and spherical lenses provides superior protection for the fiber end faces and improves signal transmission integrity.

Connector Mating Cycle Performance

One of the stand-out features of the non-magnetic expanded beam fiber optic patent is its connector mating cycle performance. The system demonstrates reliability beyond 100,000 mating cycles, ensuring robust interconnections with low maintenance and long life cycles. This makes it ideal for applications where connectors are frequently mated and unmated.

Non-Magnetic Characteristics

The patent emphasizes the use of non-magnetic metals like aluminum, silver, and titanium for various components. This makes the connectors suitable for environments requiring reduced magnetic interference, such as MRI machines. The non-magnetic properties ensure that the connectors can be used in high magnetic-field environments without compromising performance.

Detailed Technical Description

Fiber-Optic Communication

Fiber-optic connectors align pairs of termini to facilitate data transmission between devices. These connectors often house optical fibers within a cable, which can be used to transmit data between devices like MRI machines and computers. The non-magnetic expanded beam fiber optic patent describes how fiber-optic connectors can be decouplable, requiring a connector system to connect the fiber-optic lines from each device.

Physical Contact (PC) Connectors

Traditional PC connectors use spring-loaded termini to press two fiber end faces together, eliminating optical energy losses inherent in an air gap between connected fibers. Precision alignment of mated pairs of termini couples light from one fiber to the other with minimal reflection of optical energy. However, contamination of PC end faces by chips, voids, particles, liquids, etc., can disrupt signal integrity. The physical contact fiber core is exposed whenever the termini are unmated, creating numerous opportunities for contamination.

Expanded Beam (EB) Connectors

By contrast, expanded beam connectors use non-contacting optics, such as GRIN lenses and spherical lenses, to expand, collimate, and refocus the light from the transmitting fiber into the receiving fiber. This minimizes optical back reflection and significantly reduces the impact of harsh environmental factors. Expanded beam fiber optic connectors rely on the superior performance of non-contacting components to increase the durability of high-speed fiber connections.

GRIN Lenses

GRIN lenses provide superior protection for the fiber end faces and improve signal transmission integrity by significantly reducing the impact of harsh environmental factors. These lenses often use expanded beam termini to implement ultra-high-bandwidth data connections. Matching GRIN lenses to graded index fibers can significantly reduce the modal dispersion of multimode optical fiber assemblies.

Connector System Components

The non-magnetic expanded beam fiber optic patent describes various components of the optical connector system, including plug housings, pin cavities, pin sleeves, pin ferrules, socket cavities, socket sleeves, socket ferrules, and alignment sleeves. These components are made from non-magnetic metals like aluminum, silver, tin, phosphor bronze, brass, copper, gold, lead, titanium, silicon bronze, cobalt-chromium, beryllium copper, and non-magnetic stainless steel. The materials are selected to ensure minimal magnetic characteristics and high mating cycle performance.

Mating Cycle Capabilities

The connector system is designed to achieve extremely high mating cycle capabilities, facilitating low-maintenance, long life cycle, and robust optical interconnections. The socket geometry described in the patent can handle up to 1,000,000 mating cycles, ensuring reliable performance in demanding applications.

Key Features of the Non-Magnetic Expanded Beam Fiber Optic Cable Patent

Medical Imaging

In the field of medical imaging, particularly MRI systems, the non-magnetic expanded beam fiber optic patent offers significant advantages. The ruggedized electro-optical interfaces ensure reliable data transmission in high magnetic-field environments. By replacing high-count legacy radio-frequency (RF) receive image channels with multiplexed fiber-optic channels, the system improves reliability and increases the mean time between failures.

Military and Defense

In ruggedized communication systems and field-deployable networks, expanded beam connectors are preferred due to their durability and resistance to environmental factors. They ensure reliable performance in harsh conditions, making them ideal for military and defense applications.

Aerospace

Expanded beam technology is used in avionics, in-flight entertainment systems, and satellite communications. The non-contact nature of these connectors makes them ideal for applications where vibrations and environmental factors can affect performance.

Industrial Applications

In harsh factory environments, oil and gas exploration, and underwater systems, expanded beam connectors provide reliable optical connections that are less susceptible to vibration, contamination and physical damage. This ensures consistent performance in demanding industrial settings.

Intelligent Cabling

The non-magnetic expanded beam fiber optic patent incorporates intelligent cabling systems that include sensors, monitors, and micro-controllers. These systems facilitate dynamic features like auto calibration, remote monitoring, and complex system configurations. This intelligent approach ensures that the cabling system can adapt to various applications and requirements.

Benefits of Ruggedized, Non-Magnetic Expanded Beam Fiber Optic Cable

Expanded beam technology offers several significant benefits, particularly in the context of fiber-optic communication systems. Here are some of the key advantages:

Reduced Sensitivity to Contamination

- Larger Beam Area: By expanding the diameter of the light beam, any contamination (such as dust or particles) is distributed over a larger area. This reduces the impact of contaminants on signal quality.

- Non-Contact Design: The non-contact nature of expanded beam connectors means that the fiber end faces are not physically touching, which minimizes the risk of contamination and damage.

Enhanced Reliability and Durability

- No Physical Wear: Since the connectors do not rely on physical contact, there is no wear and tear on the fiber end faces. This leads to longer-lasting connections.

- High Mating Cycles: Expanded beam connectors can withstand a high number of mating cycles (often exceeding 100,000), making them ideal for applications where connectors are frequently connected and disconnected.

Improved Performance

- Low Insertion Loss: Expanded beam connectors typically offer better insertion loss performance, meaning there is less signal power loss when the light passes through the connector.

- Reduced Back Reflection: These connectors also reduce back reflection, which is the phenomenon where some of the light is reflected back towards the source, potentially causing interference.

Ruggedized for Harsh Environments

- Vibration Resilience: Expanded beam connectors are highly resilient to vibrations, making them suitable for use in environments where mechanical stability is a concern.

- Environmental Resistance: They are designed to perform well in harsh environmental conditions, including extreme temperatures, humidity, and exposure to contaminants.

Simplified Maintenance

- Low Maintenance Requirements: The non-contact design and high durability mean that expanded beam connectors require less frequent maintenance and cleaning compared to traditional physical contact connectors.

- Ease of Use: These connectors are easier to handle and less prone to damage during installation and maintenance.

High-Speed Data Transmission

- Ultra-High Bandwidth: Expanded beam technology supports ultra-high-bandwidth data connections, making it suitable for modern high-speed communication needs.

- Reduced Modal Dispersion: When used with GRIN lenses, expanded beam connectors can significantly reduce modal dispersion in multimode optical fiber assemblies, improving overall data transmission quality.

Customization and Integration

- Hybrid Capabilities: The technology can integrate both optical and electrical elements, enabling mixed-mode delivery of signals, control, timing, and data.

- Intelligent Cabling: Expanded beam connectors can be part of intelligent cabling systems that include sensors, monitors, and micro-controllers for dynamic system features like auto calibration and remote monitoring.

Expanded beam technology provides a robust, high-performance solution for fiber-optic communication systems, offering significant advantages in terms of reliability, durability, performance, and versatility. These benefits make it an ideal choice for a wide range of applications, from medical imaging and military defense to industrial and aerospace environments.

The Nortech brand is a promise—one of reimagined connections and grounded in innovation, dedication, and customer-centricity. We see an exciting future of innovation, collaboration, and growth. By redefining how we connect—internally and externally—we position Nortech as not just a solutions provider, but a trusted advisor and strategic partner. Whether you’re developing next-generation fiber optic components, navigating complex regulatory landscapes in the medical device market, or optimizing production for industrial applications, Nortech is here to help you solve the challenges of tomorrow.

With six facilities and design centers across the U.S., Latin America, and Asia, we have the global reach and localized expertise to stay by your side wherever you do business.