When You Can’t Support Your Customers

You may not be the doctor telling patients their medical tests and procedures are delayed because there aren’t enough supplies on hand. You may not be the operations officer watching your AOG (aircraft on the ground) hours rising out of control, leaving your troops immobilized and ineffective. But you might be the person telling your customers that you can’t support them because you can’t get the components and assemblies you need on time. If this rings true for you, there are ways to reduce lead times, maintain on-time deliveries and control inventory. Supply chain risk management best practices are non-negotiable. Start implementing strategic demand planning and fulfillment to meet your customer’s needs today.

Supply Chain Risks

One of the most critical aspects of supply chain management is ensuring that there is always enough inventory to meet customer demand. Maintaining these levels can be challenging, as several external and internal factors may or may not be under your control. However, there are ways to mitigate these risks, regardless of their origin.

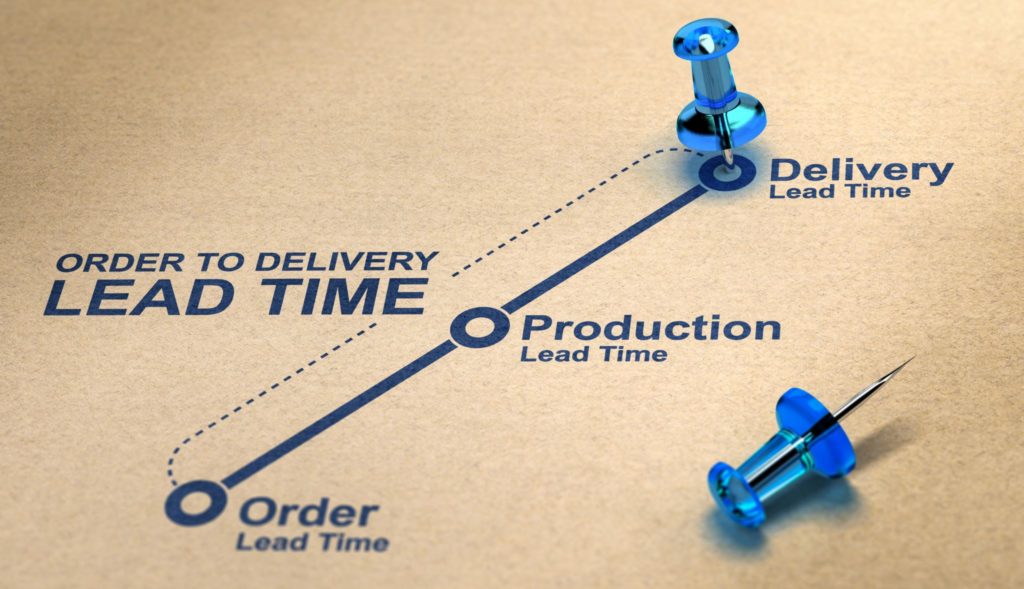

Lead Time Instability

Lead time is currently considered the number one threat to the supply chain. However, the root causes of those lead time instabilities are the real problem and often go overlooked—causes including global economic conditions, political instability, and natural disasters.

For example, 80% of the world’s neon, used to manufacture electronic components, comes from Ukraine. Current world events are resulting in extensive disruptions to that commodity, forcing the need for alternative sources.

Domestic and Global Labor Shortages

The impact of the domestic and global labor shortage on the supply chain has been significant and is largely due to the COVID pandemic and the resulting market disruptions. The domestic labor shortage has led to increased costs for businesses and reliance on foreign workers.

The global labor shortage has been exacerbated by the pandemic and government policies in China. These shortages have led to delays in shipping and disruptions in the production of goods. In some cases, the shortages have also resulted in the recall of products.

The impact of the labor shortage on the supply chain is expected to continue for some time as businesses adjust to the new reality of a global workforce.

Demand Fluctuations and Poor Demand Planning

Unpredictable or long-term changes in demand lead to disruptions further down the supply chain and have some of the same root causes as lead time instability. Poor long- and short-term forecasting practices can exacerbate these fluctuations.

Not understanding historical patterns, the product lifecycle, or their customer’s needs leads to inaccurate forecasts. Planning for current orders only and not considering the customer’s preferences, trends, and seasonal patterns are also examples of poor demand planning.

Supply Chain Risk Management Best Practices

A quick overview of the risks listed above may leave you feeling that managing your inventory is a lost cause, subject to random circumstances entirely out of your control. However, with a little less focus on the tactics of placing purchase orders and a longer-range focus on a strategic partnership with your suppliers, you can manage these seemingly daunting risks.

Create a Strategic Partnership

The first step to minimizing supply chain risk is to create a strategic partnership with your supplier. One who is partnering with you to develop the best demand plan available, take into account bigger-picture factors and create a collaborative long-term working relationship.

Working with a supplier who is aware of the bigger picture and has access to inside data sources will minimize supply chain risks. For example, a supplier that is watching progress on the CHIPS Act passed by congress regarding domestic chip manufacturing can adjust the balance of domestic and overseas supplies.

Another example of this bigger-picture thinking is a supplier working with representatives in China who proactively relays information on future pandemic lockdowns or other labor issues and can add that knowledge into a demand or production plan ahead of time instead of being blind-sided by the downstream effect after the fact.

Define Your Inputs

Another one of the supply chain risk management best practices is collaborating on an accurate demand plan. This demand plan will take into account:

- 3-4 years of past usage

- 1-3 years of future demand, which takes into account short-term forecasts, trends, and business intelligence

- Key suppliers, especially single-source or source-controlled suppliers which limit access to any strategic component or commodity

- Product lifecycle position

Level the Demand

The next step to stabilizing your inventory availability is to level the demand based on all the factors above. Collaborating with your supplier to look at long-term demand, agree to anticipated fluctuations, and decide what commitments are needed to cover not only quantity fluctuations but also timing fluctuations.

This leveled demand allows the customer to pull product as needed and triggers the next work order to be released versus building to unpredictable sales orders and shipments resulting in out of stocks and delayed shipments as needed resources are not instantly available and prevent surges in capacity utilization.

Understand Product Lifecycle and Create a Long-term Commitment

The final step to reducing supply chain risk is to consider where this finished good is in its product lifecycle. Your demand plan needs to account for new launch pipeline fills or apply a sunset plan if appropriate and develop a commitment to those longer lead time components with all of these factors in mind.

Creating a long-term commitment does not mean creating purchase orders for every component to cover the longest lead time item. It does, however, require a mutual agreement on those strategic, at-risk components, most volatile commodities, and a level of acceptable forecast fluctuation in preparation for future availability.

Expect Results

The results of these supply chain risk management best practices include:

- Finished goods inventory available when needed

- A plan for strategic components and commodities reducing reactionary buys and builds

- Improved supplier performance

- A level production plan reducing one-off jobs and capacity overloads

- Forecast tracking for easier and more accurate future demand planning

- Better cost planning

- Accurate revenue actualization

By implementing these practices, Nortech Systems has demonstrated significant results. In one customer example, the program has generated lead times of five days or less with a 95% on-time delivery metric.

Contact us to start moving away from tactical thinking and implement strategic planning to achieve results like these.